CAS 7440-05-3 Pd nanopolvo de paladio ultrafino como catalizador

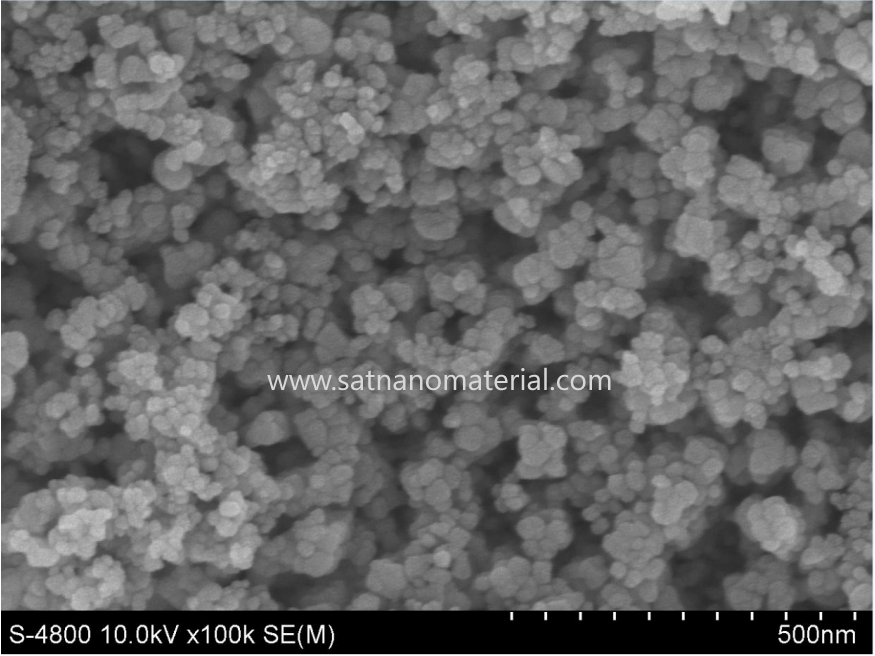

Tamaño: 20-30nm Pureza: 99.95% Nº CAS: 7440-05-3 ENINEC No.:231-115-6 Apariencia: Polvo negro Forma: esférica

Tamaño: 20-30nm Pureza: 99.95% Nº CAS: 7440-05-3 ENINEC No.:231-115-6 Apariencia: Polvo negro Forma: esférica

Podemos suministrar productos de diferentes tamaños de polvo de siliciuro de niobio de acuerdo con los requisitos del cliente. Tamaño: 1-3um; Pureza: 99.5%; Forma: granular No. CAS: 12034-80-9; ENINEC No.:234-812-3

La partícula de Ni2Si, 99.5% de pureza, forma granular, se utiliza para el circuito integrado microelectrónico, película de siliciuro de níquel, etc. Tamaño: 1-10um; No. CAS: 12059-14-2; ENINEC No.:235-033-1

En el crecimiento explosivo de los vehículos de nueva energía, las centrales eléctricas de almacenamiento de energía, la electrónica de consumo y otros campos, el "corazón" de las baterías de litio - el tamaño de partícula de los materiales activos - se está convirtiendo en la clave principal que determina el rendimiento de la batería. Desde la batería Tesla 4680 hasta la batería CATL Kirin, desde el fosfato de hierro y litio hasta el electrodo positivo ternario, el ajuste a nivel micrométrico del tamaño de partícula del material afecta directamente la velocidad de carga y descarga, la vida útil e incluso el límite de seguridad de la batería.

¿Por qué los gigantes tecnológicos persiguen la nanoescala?

Según la ley de Fick, el tiempo de difusión de los iones de litio dentro de una partícula es proporcional al cuadrado del radio de la partícula. Las nanopartículas (<100 nm) acortan la trayectoria de difusión de los iones de litio a 1/10 de la de las partículas de tamaño micrométrico, lo que reduce significativamente la resistencia a la difusión en fase sólida. Por ejemplo, después de reducir el tamaño de las partículas de fosfato de hierro y litio (LiFePO₄) de 5 μm a 100 nm, la conductividad iónica aumenta tres veces, lo que permite una carga y descarga a alta velocidad superior a 10C; ·El material catódico ternario (NCM) adopta agregados de nanopartículas primarias, que pueden mantener el 85 % de la capacidad a una temperatura elevada de 45 ℃

2. La "red densa" de partículas conductoras electrónicamente forma puntos de contacto más densos en el electrodo, lo que teóricamente mejora la eficiencia de la conducción de electrones. Los datos experimentales muestran que el área de contacto de las nanopartículas de óxido de cobalto de litio (LiCoO₂) aumenta en un 40 % y la resistencia del electrodo disminuye en un 25 %. En el electrodo negativo compuesto de nanotubos de carbono, la densidad de puntos de contacto entre las nanopartículas de silicio y el agente conductor se triplica y la eficiencia supera el 90 % por primera vez.

3. El "innovador" del rendimiento a baja temperatura exhibe una cinética de desintercalación de iones de litio más rápida en nanopartículas en un entorno de baja temperatura de -20 °C. Según las pruebas reales de una determinada marca de vehículos eléctricos, las baterías que utilizan nanoelectrodos positivos aún pueden liberar el 85 % de su capacidad a -15 °C, mientras que los materiales tradicionales solo pueden liberar el 60 %

4. El pequeño tamaño de partícula del "contraatacante" de la vida útil del ciclo puede aliviar el gradiente de tensión de concentración durante la carga y descarga profundas. Según datos del Laboratorio Ningde Times, la tasa de retención de capacidad de los nanomateriales ternarios alcanza el 82 % después de 3000 ciclos, lo que es un 15 % superior a la de los materiales a nivel de micras.

El "daño fatal" del pequeño tamaño de partícula: ¿cómo resolver los tres principales peligros ocultos?

1. Fenómeno de aglomeración: La elevada superficie específica (hasta 100 m²/g) de las nanopartículas, desde el "canal eficiente" hasta la "isla de la muerte", provoca un aumento significativo de la energía superficial, lo que incrementa la probabilidad de aglomeración. Por ejemplo, tras la agregación de nanopartículas de fosfato de hierro y litio en la suspensión, aparecen poros de 20 μm en el electrodo recubierto, lo que triplica la densidad de corriente local. Una investigación sobre un accidente en una central de almacenamiento de energía demostró que la aglomeración de los materiales del electrodo positivo causó un cortocircuito interno y una temperatura que se elevó a 300 °C, provocando pérdidas de calor. Solución: Tecnología de recubrimiento superficial: Recubrir las nanopartículas con capas de carbono u óxidos para reducir la energía superficial. Optimización del dispersante: Se utilizan dispersantes no iónicos para controlar la viscosidad de la suspensión por debajo de 6000 mPa·s.

2. Tormenta de reacciones secundarias: El área de contacto entre las nanopartículas de la "bomba de combustión" a nanoescala y el electrolito aumenta 10 veces, lo que provoca: · Descomposición del electrolito: Las nanopartículas catalizan la oxidación del electrolito a altas temperaturas, lo que resulta en un aumento de 5 veces en la producción de gas; · Disolución de iones metálicos: El óxido de níquel, cobalto, manganeso y litio (NCM) a nanoescala tiene una tasa de disolución de metal del 0,3 %/ciclo a un alto voltaje de 4,5 V, que es el doble que la de los materiales a escala micrométrica. Solución: · Aditivos para el electrolito: Introducir aditivos formadores de película como el FEC (carbonato de vinilo fluorado) para suprimir las reacciones secundarias; · Optimización de la ventana de voltaje: Reducir el voltaje de corte de carga de 4,3 V a 4,2 V y aumentar la vida útil del ciclo en un 40 %

3. Pesadilla del proceso: La producción a gran escala de nanomateriales, desde el "sueño nano" hasta el "pozo de producción en masa", enfrenta tres desafíos principales: dificultad de dispersión: requiere el uso de molinos de arena de alto cizallamiento, que consumen tres veces más energía que los materiales de tamaño micrométrico; · Costo de las pruebas: La frecuencia de las pruebas con analizador de tamaño de partículas láser debe aumentarse a 3 veces por lote, lo que resulta en un aumento del 50 % en el costo; · Desgaste del equipo: Las nanopartículas aumentan la tasa de desgaste de las perlas de circonio en los molinos de arena en 10 veces, y el ciclo de mantenimiento se reduce a 72 horas. Solución:

· Granulación en seco: Preaglomerar las nanopartículas en partículas secundarias de tamaño micrométrico, equilibrando el rendimiento y el proceso; · Detección en línea: Introducir la tecnología de análisis de procesos (PAT) para monitorear la distribución del tamaño de las partículas en tiempo real.

Tamaño de las nanopartículas, ¿es el punto final o el punto de partida? Los materiales de partículas pequeñas son como un arma de doble filo, ya que confieren a las baterías un rendimiento extraordinario, pero también plantean desafíos en términos de fabricación y seguridad

SAT NANO es uno de los mejores proveedores de nanopartículas y partículas micrométricas en China; podemos ofrecer polvo de cobre , polvo de silicio y otros productos para baterías. Si tiene alguna consulta, no dude en contactarnos en admin@satnano.com

Servicio en línea

Servicio en línea 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449