CAS 7440-05-3 Pd nanopolvo de paladio ultrafino como catalizador

Tamaño: 20-30nm Pureza: 99.95% Nº CAS: 7440-05-3 ENINEC No.:231-115-6 Apariencia: Polvo negro Forma: esférica

Tamaño: 20-30nm Pureza: 99.95% Nº CAS: 7440-05-3 ENINEC No.:231-115-6 Apariencia: Polvo negro Forma: esférica

Podemos suministrar productos de diferentes tamaños de polvo de siliciuro de niobio de acuerdo con los requisitos del cliente. Tamaño: 1-3um; Pureza: 99.5%; Forma: granular No. CAS: 12034-80-9; ENINEC No.:234-812-3

La partícula de Ni2Si, 99.5% de pureza, forma granular, se utiliza para el circuito integrado microelectrónico, película de siliciuro de níquel, etc. Tamaño: 1-10um; No. CAS: 12059-14-2; ENINEC No.:235-033-1

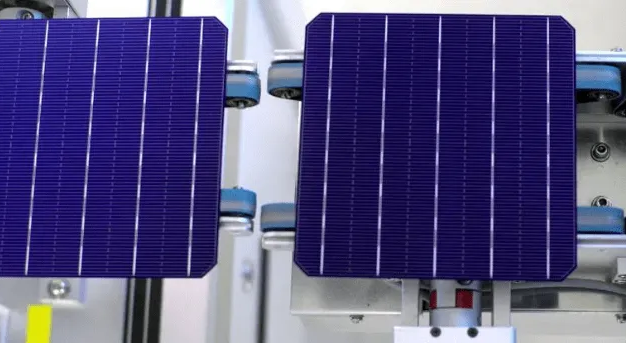

Actualmente, la industria fotovoltaica está acelerando su iteración hacia la tecnología eficiente de baterías de tipo N, y las células de heterojunción (HJT) se han convertido en una dirección de desarrollo muy prometedora gracias a sus destacadas ventajas, como la alta eficiencia de conversión, el bajo coeficiente de temperatura y la alta relación bicapa. Sin embargo, debido a la estructura de generación de energía de doble cara utilizada por las HJT, es necesario recubrir ambas caras de la batería con pasta de plata de baja temperatura, lo que resulta en un consumo de polvo de plata mucho mayor que el de las células PERC de una sola cara. El alto coste del polvo de plata se ha convertido en un obstáculo clave que limita su comercialización a gran escala y una mayor reducción de costes. Con el objetivo principal de promover continuamente la reducción de costes y la mejora de la eficiencia en la industria fotovoltaica, es urgente encontrar un sustituto para el polvo de plata.

En comparación con el polvo de plata, el polvo de cobre presenta una gran ventaja en cuanto a costo gracias a su precio extremadamente bajo. Sin embargo, su mayor desventaja inherente es su alta susceptibilidad a la oxidación. En entornos de preparación y uso de electrodos, su conductividad se deteriora drásticamente debido a la oxidación, lo que dificulta el cumplimiento de los requisitos de funcionamiento confiable a largo plazo de las células fotovoltaicas. Por lo tanto, la tecnología de polvo de cobre recubierto de plata, que combina ventajas en costo y posibles garantías de rendimiento, se ha convertido en una importante línea de investigación para la reducción de costos de baterías estructuradas de doble cara como las HJT.

El polvo de cobre recubierto de plata se forma recubriendo de forma uniforme y continua una capa de plata de entre decenas y cientos de nanómetros sobre la superficie del polvo de cobre, formando una típica estructura de núcleo-capa. Esta estructura especial permite que el núcleo de cobre ocupe la mayor parte de la masa del polvo, reduciendo significativamente el consumo de plata metálica, un metal costoso. Además, confiere al polvo de plata y cobre excelentes propiedades similares a las del polvo de plata pura:

1. Actividad antioxidante

La capa de plata densa y químicamente inerte en la superficie del polvo de cobre recubierto de plata actúa como una barrera física, aislando eficazmente el núcleo de cobre interno del entorno externo (oxígeno, humedad), retrasando así significativamente el proceso de oxidación del núcleo de cobre.

2. Conductividad: Como relleno conductor en electrodos, el polvo de cobre recubierto de plata puede conducir la corriente a través de una capa de plata externa. En teoría, una capa de plata bien recubierta garantiza una conducción eficaz de la corriente en la superficie del electrodo, proporcionando una alta conductividad cerca de la superficie del polvo de plata.

Con la aceleración de la iteración tecnológica, especialmente en colaboración con los procesos emergentes de baterías de baja temperatura como la HJT, el potencial de aplicación industrial del polvo de cobre recubierto de plata está emergiendo gradualmente. Sin embargo, la introducción del elemento de cobre ha generado inquietud sobre su confiabilidad a largo plazo. Cómo garantizar que el cobre no se oxide ni migre durante el funcionamiento a la intemperie de las baterías de cobre recubierto de plata durante muchos años es una preocupación común tanto para las fábricas de pasta como para las de componentes. Además, el método de recubrimiento químico convencional actual tiene un proceso de preparación complejo que requiere un control preciso de parámetros como la composición de la solución de recubrimiento, la temperatura de reacción y el tiempo para producir polvo de cobre recubierto de plata estructuralmente estable y con un recubrimiento uniforme. Por lo tanto, aún queda por demostrar en la práctica si el polvo de cobre recubierto de plata puede reemplazar al polvo de plata fotovoltaico a gran escala. Sin embargo, se puede confirmar que, con la optimización continua de la tecnología de preparación, el polvo de cobre recubierto de plata sigue siendo una de las vías de exploración importantes para promover la reducción continua de costos en la industria fotovoltaica.

SAT NANO es uno de los mejores proveedores en China, podemos ofrecer polvo de plata y polvo de cobre recubierto de plata Con alta calidad, si tiene alguna consulta, contáctenos en admin@satnano.com

Servicio en línea

Servicio en línea 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449