En la actualidad, las tecnologías de modificación superficial del micropulver de sílice esférico incluyen principalmente la modificación orgánica, la modificación por corrosión química y la modificación por injerto de polímeros.

1. Modificación orgánica

La modificación orgánica consiste en la introducción de grupos funcionales procedentes de compuestos orgánicos en la superficie del micropulver de sílice esférico. Esto altera sus propiedades superficiales y mejora significativamente la adhesión interfacial entre el micropulver de sílice esférico y la matriz orgánica, aumentando así la dispersabilidad y la fluidez del micropulver de sílice esférico en dicha matriz. El micropulver de sílice esférico modificado orgánicamente presenta ventajas significativas al mejorar la compatibilidad entre el micropulver de sílice esférico y la matriz orgánica, incrementando la fluidez y permitiendo su uso en aplicaciones de alta gama.

Debido a la amplia variedad de modificadores orgánicos, la investigación teórica en profundidad sobre los mecanismos de modificación, los procesos de modificación maduros y la facilidad de operación y control, han sido ampliamente estudiados y aplicados en el campo industrial.

Existen numerosos compuestos orgánicos empleados en la modificación orgánica, entre los que destaca el agente de acoplamiento de silano por su uso común. Este agente presenta una amplia variedad, un extenso rango de aplicaciones y cuenta con el sistema industrial más completo.

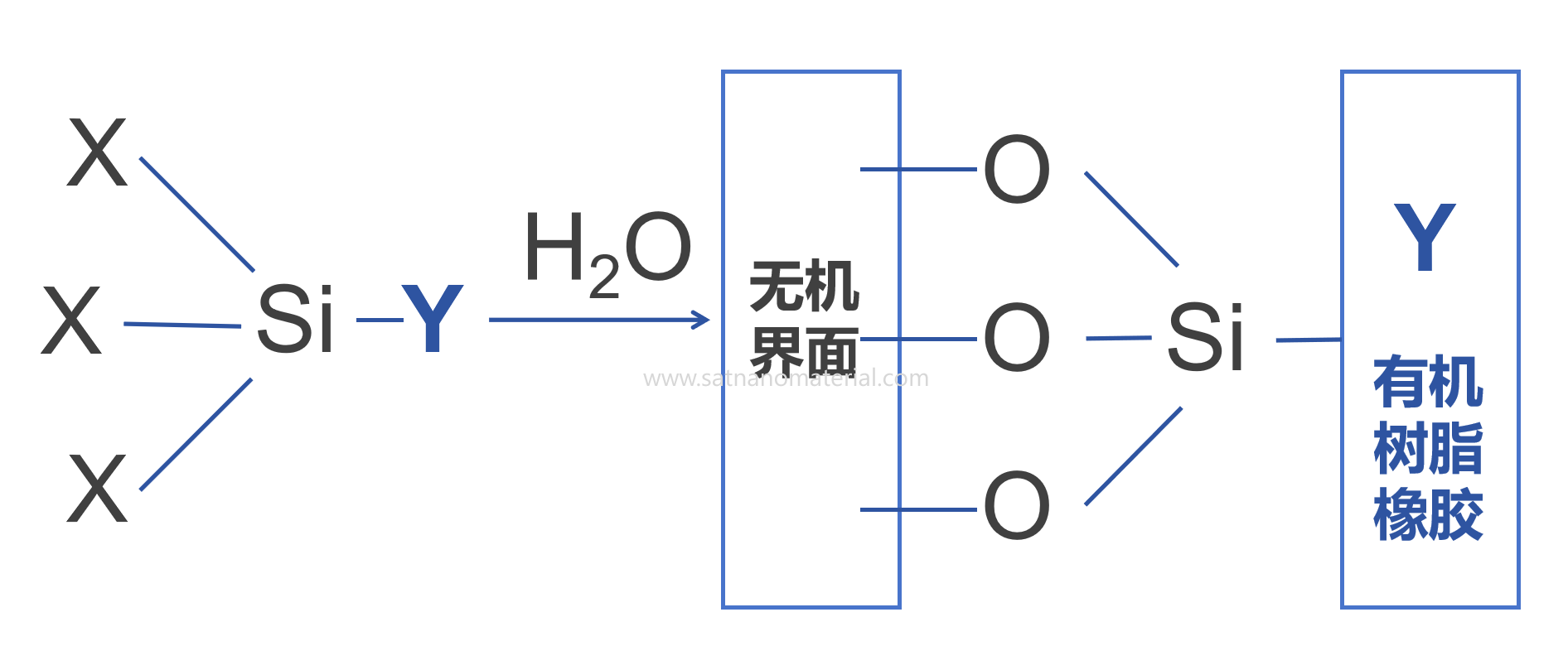

La estructura molecular de los agentes de acoplamiento de silano contiene grupos funcionales como epoxi, vinilo y amino que interactúan con compuestos orgánicos, así como grupos alcoxilo que pueden hidrolizarse y unirse a los grupos hidroxilo de la superficie de las micropartículas de silicio. Según la teoría del enlace químico, un extremo del agente de acoplamiento de silano reacciona con los grupos funcionales de los compuestos orgánicos, mientras que el grupo alcoxi del otro extremo se hidroliza e interactúa con los grupos hidroxilo de la superficie de las micropartículas de silicio. Durante este proceso, el agente de acoplamiento de silano sufre hidrólisis, condensación y forma enlaces de hidrógeno, formando finalmente un fuerte enlace covalente silicio-oxígeno con las micropartículas de silicio.

SAT NANO et al. utilizaron tres tipos de agentes de acoplamiento de silano (viniltrimetoxisilano, 3-metilacriloiloxipropiltrimetoxisilano y 3-glicidoxipropiltrimetoxisilano) para modificar la superficie de micropartículas esféricas de silicio, generando soluciones orgánicas de silicio estables a altas concentraciones. Posteriormente, las mezclaron con resina epoxi y compararon los efectos de modificación de estos tres agentes de acoplamiento de silano. Aplicaron las micropartículas esféricas de silicio modificadas como relleno en laminados revestidos de cobre y estudiaron el efecto de dichas modificaciones en las propiedades de estos laminados. La investigación demostró que el rendimiento de los laminados revestidos de cobre rellenos con micropartículas esféricas de sílice modificadas con 3-metilacriloiloxipropiltrimetoxisilano fue el mejor. Los grupos vinilo y alquilo del 3-metilacriloiloxipropiltrimetoxisilano se unieron a la superficie de las micropartículas esféricas de sílice, exhibiendo una excelente estabilidad de dispersión a altas concentraciones de estas micropartículas. En comparación con la resina epoxi original, la resistencia a la tracción del material compuesto de resina epoxi con micropartículas esféricas de silicio ha aumentado un 38 %. En comparación con el laminado revestido de cobre sin micropartículas esféricas de silicio, el laminado revestido de cobre que contiene micropartículas esféricas de silicio presenta un mayor módulo de almacenamiento, una temperatura de transición vítrea más alta y una mayor resistencia al despegue.

SAT NANO et al. utilizaron bis-[3-(trietoxisilicon)propil]-tetrasulfuro y 3-octiltiol-1-propiltrietoxisilano para modificar polvo de sílice esférico. La investigación reveló que, con la adición de agentes de acoplamiento de silano, se reduce el tiempo óptimo de curado de los materiales compuestos y se prolonga el tiempo de combustión. La resistencia al deslizamiento en húmedo del material compuesto mejoró un 14,0 % al modificarlo con bis-[3-trietoxisililpropil]-tetrasulfuro, mientras que la resistencia a la rodadura se redujo un 19,6 % al modificarlo con 3-octanoiltio-1-propiltrietoxisilano, lo que mejora la seguridad del procesamiento. Esto se debe a que, tras la modificación con el agente de acoplamiento de silano, la fluidez y la compatibilidad con la matriz del micropulver de sílice esférico mejoraron, potenciando la interacción con la matriz de caucho.

Debido a las diferencias en los grupos funcionales de los distintos agentes de acoplamiento de silano, cuando se combinan dos o más tipos de modificadores para modificar micropulveres esféricos de sílice, el efecto de modificación suele ser mejor que el de un solo modificador.

SAT NANO y otros combinaron sinérgicamente tres tipos diferentes de agentes de acoplamiento de silano (γ-aminopropiltrietoxisilano, γ-glicidoxipropiltrimetoxisilano y feniltrimetoxisilano) para lograr la funcionalización deseada, sintetizando micropartículas esféricas de sílice con un tamaño promedio de 700 nm, modificadas con tres grupos funcionales. Los resultados de la investigación indican que estos modificadores confieren grupos funcionales reactivos, incluyendo grupos epoxi y amino, a las micropartículas esféricas de sílice, mejorando la compatibilidad interfacial y la adhesión entre las micropartículas de sílice y la matriz de resina epoxi. Además, la introducción de grupos fenilo no reactivos contribuye a reducir la viscosidad de los materiales compuestos de resina. Estas micropartículas esféricas de sílice modificadas se integran en la fórmula del sellador, demostrando una excelente fiabilidad y procesabilidad. En comparación con el sellador preparado con micro polvo de sílice esférica no modificada, el sellador modificado tiene una disminución del 95% en la permeabilidad a la humedad, un aumento en la temperatura de transición vítrea de aproximadamente 30 ℃ y una disminución en el coeficiente de expansión térmica de 5 × 10-6 ℃ -1.

SAT NANO et al. investigaron el efecto de la modificación simultánea con dimetildimetoxisilano y trimetiletoxisilano, y con metiltrimetoxisilano y propiltrimetoxisilano, en compuestos de resina epoxi con micropartículas esféricas de sílice. Observaron que las micropartículas esféricas de sílice modificadas mejoran significativamente la hidrofobicidad, la dispersabilidad y la compatibilidad con las resinas epoxi. Entre ellas, la modificación simultánea con metiltrimetoxisilano y propiltrimetoxisilano resultó ser la más efectiva. En comparación con las micropartículas esféricas de sílice sin modificar, la conductividad térmica del material compuesto de resina epoxi con micropartículas esféricas de sílice modificadas con metiltrimetoxisilano y propiltrimetoxisilano aumentó un 42,6 %, y la resistencia a la tracción, un 28,0 %. Además, las propiedades mecánicas como la resistencia a la flexión, la resistencia al impacto y la resistencia a la tracción de los materiales compuestos modificados superan las de los materiales compuestos de resina epoxi con micropulverización esférica de sílice no modificados.

2. Modificación química de la corrosión

Debido a la superficie lisa y la fuerte inercia química del micropulver esférico de sílice, a menudo se presentan situaciones en las que la tasa de composición efectiva del modificador es baja y el efecto de modificación es deficiente. La modificación por corrosión química consiste en el uso de reactivos altamente corrosivos para grabar la superficie del micropulver esférico de silicio, alterando así su morfología o propiedades superficiales, generando más sitios activos y mejorando el efecto de modificación.

SAT NANO trató micropulverizados esféricos de silicio con una solución de hidróxido de sodio a 95 °C y estudió la influencia de las características superficiales de dichos micropulverizados en el rendimiento y las características estructurales de los fotocatalizadores (dióxido de titanio y sulfuro de cadmio), así como la interacción en la interfaz entre el semiconductor y el portador. Los resultados mostraron que, tras el tratamiento con hidróxido de sodio, se incrementaron la actividad y la hidroxilación de la superficie de los micropulverizados esféricos de silicio, lo que aumentó los puntos de anclaje y la dispersión de las nanopartículas, mejoró la separación de carga y la interacción interfacial entre el semiconductor y el portador, indujo el transporte direccional de los portadores fotogenerados y mejoró el rendimiento fotocatalítico del fotocatalizador.

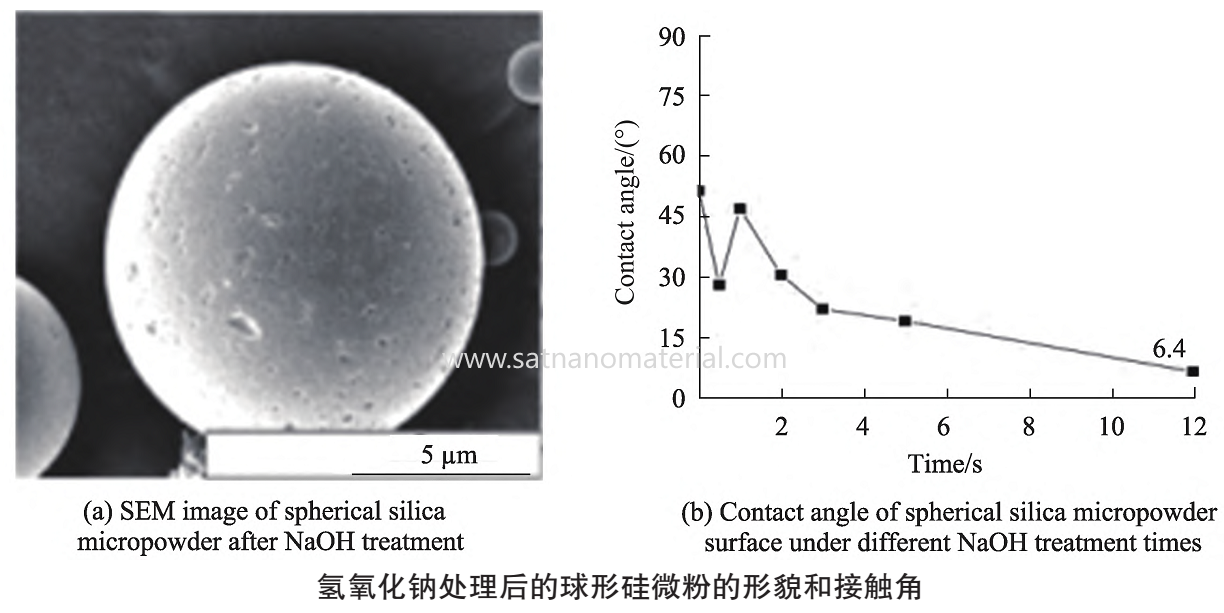

SAT NANO utiliza primero hidróxido de sodio para grabar la superficie de micropartículas de silicio esféricas y, posteriormente, las modifica con un agente de acoplamiento de silano. Los resultados de la investigación indican que, tras el grabado con hidróxido de sodio, la morfología superficial y la hidrofilicidad de las micropartículas de silicio esféricas se modifican. La superficie de las micropartículas de silicio esféricas, tras el grabado con hidróxido de sodio, presenta numerosas cavidades y un aumento de la rugosidad superficial. Con el aumento del tiempo de grabado, el ángulo de contacto de las micropartículas de silicio esféricas disminuye gradualmente, lo que indica un incremento de su hidrofilicidad. Tras el tratamiento con hidróxido de sodio, las micropartículas de silicio esféricas se modificaron con gamma-metacriloiloxipropiltrimetoxisilano y gamma-glicidoxipropiltrimetoxisilano, respectivamente. En comparación con el efecto de modificación obtenido al usar directamente gamma metacriloiloxipropiltrimetoxisilano y gamma glicidoxipropiltrimetoxisilano, la resistencia al impacto de la muestra compuesta aumentó un 2,5 % y un 21,6 %, la resistencia a la flexión un 18,2 % y un 25,9 %, y la conductividad térmica un 6,32 % y un 11,82 %, respectivamente. Los resultados de la investigación indican que, tras el grabado con hidróxido de sodio, se forman más sitios activos en la superficie del micropulver de silicio esférico, lo que mejora el efecto de modificación superficial del agente de acoplamiento de silano sobre dicho micropulver.

En resumen, tras la modificación de la superficie, la dispersabilidad y la fluidez del micropulver de sílice esférico en la matriz orgánica mejorarán significativamente, potenciando así el rendimiento de los materiales compuestos.

SAT NANO es el mejor proveedor de microesferas dióxido de silicio (SiO2) en polvo En China, podemos suministrar nanopartículas de 100 nm, 300 nm, 500 nm y 1000 nm. Si tiene alguna consulta, no dude en contactarnos a través de admin@satnano.com.

Servicio en línea

Servicio en línea 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449